Robert Hofmann GmbH Rapid Prototyping:

With rapid prototyping, not only does your vision become reality, but it also accelerates your innovative power.

In the crucial development phase, we use our advanced rapid prototyping approach to identify potential for improvement and insights at an early stage. These findings are not only crucial for the quality of the prototypes, but also form the foundation for later series production.

We understand that every project is unique.

We offer tailor-made solutions that are tailored precisely to your individual requirements. No matter how complex your ideas are – we adapt and make the impossible possible.

Interested? We would be happy to introduce ourselves.

Trust in our expertise to implement your ideas efficiently, precisely and promptly. Our employees are not only experts in their field, but also partners who use their skills to make your visions come true in all aspects – be it in terms of functionality or attractive design.

For us, rapid prototyping goes beyond the traditional framework

We don’t just manufacture individual components.

Our offer also extends to the construction of aluminum tools through our special speed system tooling concept. This makes it possible to produce prototypes using injection molding in the original material – and with the shortest lead times. In addition, the production and assembly of entire assemblies are one of our strengths, which our customers particularly value.

Our service does not end with the delivery of the prototypes.

We offer a comprehensive after-sales service to ensure that you are completely satisfied with the products delivered. Our dedicated team is available to answer any questions you may have, provide support and ensure your needs are met post-purchase.

Process in rapid prototyping:

Innovation in perfection

Rapid prototyping is revolutionizing the way ideas are transformed into tangible reality. At Robert Hofmann GmbH, we offer a wide range of advanced rapid prototyping processes that push the boundaries of innovation and enable tailor-made solutions for our customers. Here is an overview of our different procedures:

Metal 3D printing:

Our state-of-the-art metal 3D printing enables the precise production of metallic components and prototypes. This technology can be used to realize complex shapes and structures in various metals, enabling a wide range of applications in various industries.

Plastic 3D printing:

Plastic 3D printing offers a flexible and cost-efficient method for producing prototypes and small series. This process enables the rapid production of detailed and complex plastic parts that are ideal for design iterations and functionality testing.

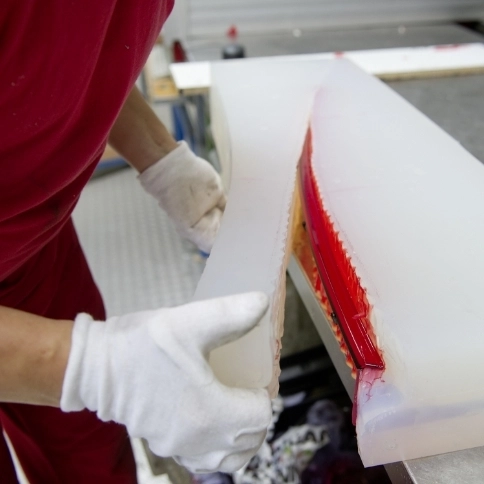

PU vacuum casting:

PU vacuum casting is a proven method for the cost-effective production of small series and prototypes made of plastic. A silicone mold is used to produce highly precise and detailed parts that meet the requirements for functionality and aesthetics.

Aluminum tools:

Our speed system tooling concept in rapid prototyping enables the rapid production of prototypes from original materials using injection molding processes. This process is particularly efficient when it comes to producing prototypes using original material and enables the shortest throughput times.

Our offer as part of the Rapid Prototyping: Our comprehensive offering

The area of rapid prototyping goes beyond mere production to ensure that your projects become successful.

We understand that every project is unique.

Our goal is not only to produce prototypes, but also to realize your ideas and make your projects a success.

With our advice, design optimization and our dedicated after-sales service, we offer you all-round support that goes beyond the standard. Rely on Robert Hofmann GmbH as your reliable partner.